The Buzz on Sheroz Earthworks

The Buzz on Sheroz Earthworks

Blog Article

The Main Principles Of Sheroz Earthworks

Table of ContentsSheroz Earthworks Things To Know Before You Get ThisThe 8-Minute Rule for Sheroz EarthworksOur Sheroz Earthworks PDFsSheroz Earthworks Fundamentals ExplainedThe Best Strategy To Use For Sheroz Earthworks

For any type of earthwork professional, it is important to do job with high quality, precision, and on time. Utilizing equipment control in job machines enables maximizing the different phases in the earthwork process, from intending to the upkeep stage - trimble tripod parts. The machine control system aids the maker driver in obtaining the target plane rapidly and quickly

The equipment control system guides the driver with centimeter accuracy. Remote support saves time and cash, as it reduces downtime in jobsites.

What Does Sheroz Earthworks Do?

Our system's parts are thoroughly created to endure the rough problems of building sites. Contrast of the very same job performed using maker control versus the typical approach exposes that, on average, the standard approach requires 50% even more time to complete the very same job as the technology-assisted approach.

Get in the Xsite equipment control system; it's right here to provide you with a substantial advantage when working with earthmoving machinery. Discover exactly how Xsite Maker Control can enhance your efficiency and guarantee work safety! Xsite Machine Control systems can be mounted to any kind of excavator from mini excavators to large mining excavators.

Exactly how does maker control job? In 2D systems, the maker is outfitted with calibrated disposition sensing units.

The system is really easy to discover the essentials can be shown in under one hour of training. How does the remote assistance job? A wireless web connection makes it feasible to develop a remote link in between the maker control system and the service.

7 Simple Techniques For Sheroz Earthworks

What sort of information formats Xsite systems support? Xsite Device Control systems sustain open common documents layouts, making it possible for smooth details flow from one system to one more. Supported data formats: 2D-Maps: DXF Point documents: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Area Models: DXF, XML What elements are set up on my equipment? Depending upon your choice of system (with or without positioning, i.e - topcon., 2D or 3D), your maker is geared up with disposition sensors, a controller unit, and a display/operating panel.

Several software and hardware solutions exist to aid determine a device's present placement on the earth and contrast it with a preferred layout surfaceand building drivers can do more to utilize the advantages. Equipment control is making use of various positioning sensors and a display screen to offer the driver with a reference in between the setting of the pail or blade and the target grade.

Depending upon the configuration, maker control systems can offer the driver with an easy aesthetic guide to container or blade setting, or can immediately relocate the blade to quality by speaking to the equipment's hydraulics - https://qualtricsxmkpyy9kbs2.qualtrics.com/jfe/form/SV_3IOcfD5rXwnI6x0. There are machine control systems available for almost any type of device: , dozers, excavators, soil and asphalt compactors, scrapes, click over here leaners, crushing machines, and pavers

Sheroz Earthworks Can Be Fun For Anyone

Some benefits include reduced rework, enhanced task effectiveness, and reduced checking expenses. Device control can likewise aid raise performance and minimize overall costs. This innovation is changing the method the construction market functions. Building devices without machine control will come to be a distant memory and the benefits acquired from it will be countless.

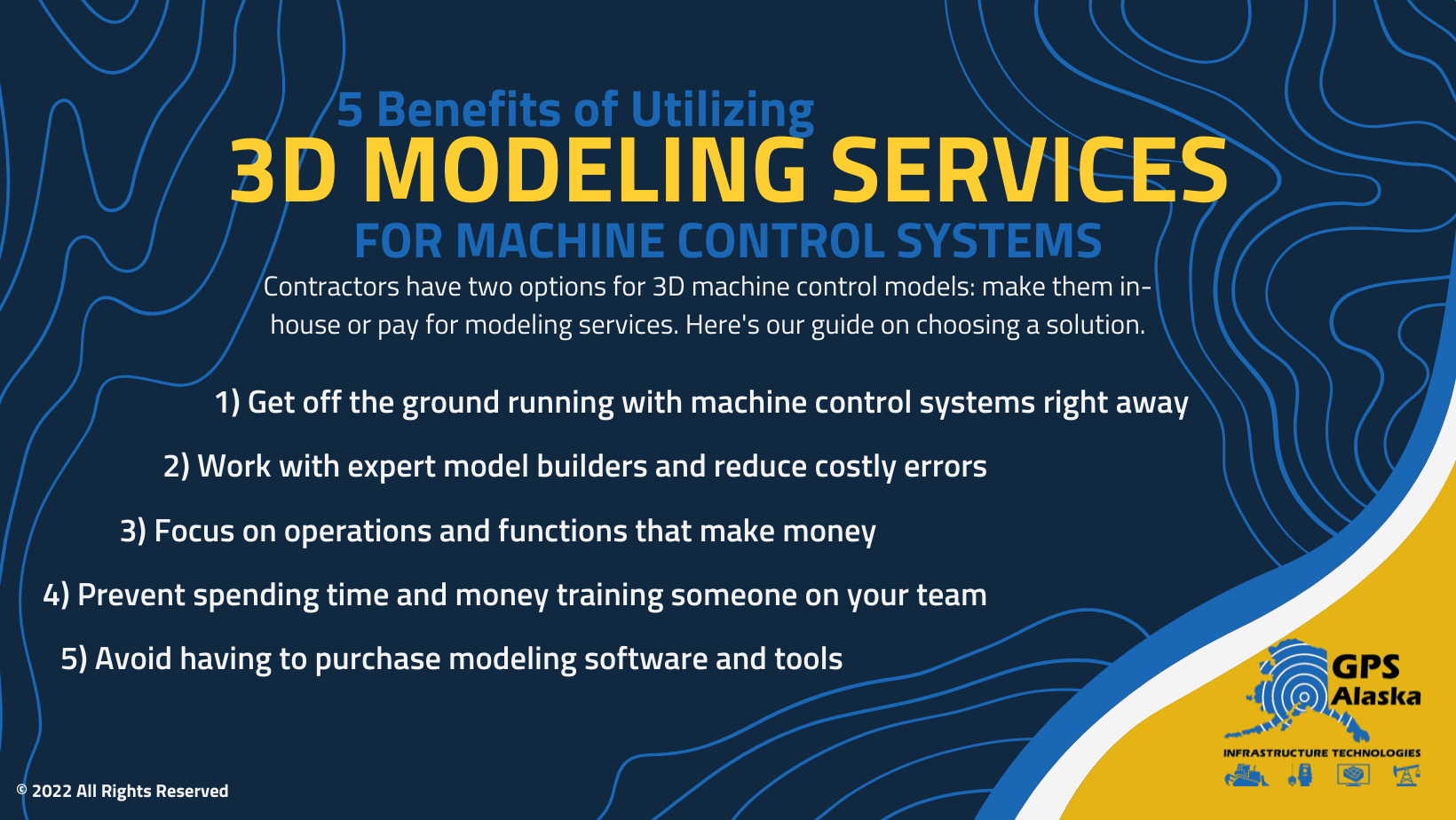

Trimble maker control systems offer a myriad of advantages to anybody who makes use of earthwork machinery and, at EarthCalc, we can provide you with 3D apply for your device control-enable tools. Unsure if equipment control deserves the cost? Take into consideration the adhering to reasons that you require to consider this alternative.

Using GPS aligned with your 3D layout files, these systems virtually assure that you will get rid of or put the right quantity of product at the building and construction website. On most building websites, remodel is a typical and discouraging reality, however with Trimble maker control, you can eliminate the demand for rework.

Get This Report on Sheroz Earthworks

Usually, with Trimble machine control, you can remove excess devices at a specific task site. For example, a task that might have needed the usage of 3 or four items of digging deep into equipment currently could require just 2 tools to achieve the very same job in less time. This enables you to relocate your tools to one more work website and handle multiple work at one time.

Report this page